|

|

|

|

Hyspan Barco Ball Joints provide a method of absorbing pipe movement for

applications ranging from steam and hot water pipe expansion, tank and building

settlement, seismic isolation, wave motion compensation on oil platforms and

drill ships, solar panel movement, oil well riser expansion and safety relief

valve escape piping.

|

|

The unique design of Hyspan Barco Ball Joints allows disassembly for inspection,

seal replacement or other maintenance resulting in a product that lasts a

lifetime.

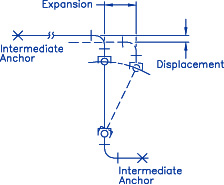

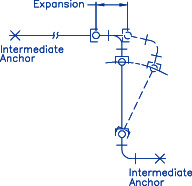

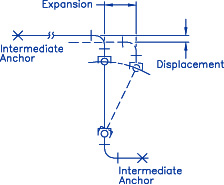

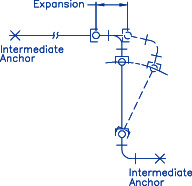

The Hyspan Barco Off-Set® Method utilizes two or three ball joints installed in

a leg of the piping or a loop with the motion perpendicular to two ball joints

installed in tandem. Two ball joints are satisfactory for most applications - a

third joint may required for large movements.

|

Two ball joint installation.

|

|

Three ball joint installation.

|

|

|

|

|

|

|

Applications

Hyspan Barco Ball Joint Applications

Details the many uses of ball joints in piping systems. Includes recommended

layouts with methods of calculation of motions, forces and moments.

Oil Field Steam Injection

Scissor linkage incorporating ball joints designed to absorb well head growth

for steam injection wells in oil fields.

Solar Panel Connections

Ball joint configurations for the heat transfer oil piping connecting the main

header and crossover between mirrors for parabolic trough solar panels. Allows

panels to rotate to track the sun.

Tank Settlement

Recommended ball joint installation for piping connections to tanks to

compensate for displacement resulting from soil conditions.

Standard Catalog Ball Joint Designs

Hyspan Barco Ball Joints are available in standard and custom configurations

1/2" through 30" nominal pipe size. The following configurations are available

that will meet most requirements. Contact

websales@Hyspan.com for additional sizes through 48" or special design

requirements.

Type N Style I Ball Joints

Type N Style I Hyspan Barco Ball Joints have evolved from the original ball

joints that were developed by Barco in 1908 to distribute steam from locomotives

to passenger cars for heating. The Type N Style I was developed in 1960. Since

that time thousands of Style I joints have been installed in steam, hot water

and chilled water distribution systems, used to absorb tank and building

settling, used for seismic isolation and many other piping applications to

compensate for expansion or to add flexibility to the system. Type N Style I

joints are available from 2 1/2" through 30" with Hyspan Barco proprietary

Compound 11 composition seals or Compound 24 glass filled Teflon® seals. Type N

Style I joints have a bolted retainer that permits seal adjustment or

disassembly for maintenance.

Type N Styles II, III & III-V Ball

Joints

Type N Style II, III & III-V ball joints are designed with injected graphite

flakes with synthetic oil carrier, Grafoil® Flexible Graphite, that provides

lubrication in addition to sealing. Grafoil® combined with a variety of high

strength bearing materials results in increased temperature and pressure

ratings. Seal options include Hyspan Barco Compound 11 non-metallic composition

material, Number 21 ductile iron, Number 39 Alloy 625 high nickel stainless

steel and Number 45 chrome-moly steel.

All Type N Style II, III & III-V ball joints permit repacking with Grafoil®

after installation. Packing of Type N Style II ball joints is accomplished with

the system pressure removed and the installation of a Recharge Cylinder. The

Recharge Cylinders are a permanent part of Type N Style III & III-V thus

permitting repacking with the system operating. The Style III-V has the added

benefit of a Safety Valve to completely isolate the system pressure.

|

|

|

ASME Class Hyspan Barco ball joints installed in flowline/riser connection of

offshore platform.

|

ASME Class Ball Joints

Class150 through 2500

Hyspan Barco ASME Class ball joints have been designed to conform to the ratings

established for ASME butt weld valves at 100ºF. Standard configurations are

available 2" through 12" NPS for class 150 through 2500.

The sealing system combines ductile iron or alloy steel with injected graphite

flakes with synthetic oil carrier, Grafoil® Flexible Graphite. Grafoil® packing

can be injected after installation if necessary.

ASME Class Ball Joints have been fire tested in accordance with API 6FA and

approved by ABS Americas and Lloyd's Register for shipboard applications.

OW1500 Style II and III-V Ball Joints

OW1500 Ball Joints are designed for 1500 psig and temperatures to 650ºF.

They are commonly used to compensate for riser expansion on oil field wellheads,

to compensate for solar panel rotation and other high-pressure applications.

OW1500 joints have ductile iron seals in combination with injected graphite

flakes with synthetic oil carrier, Grafoil® Flexible Graphite. OW 1500 ball

joints are designed to be repacked in service.

Type Standard Series, Type 600, Type 14000: Consult factory for

assistance

Standard Series Ball Joints are made from ductile iron or wrought steel

is sizes ranging from 1/2" through 2". Straight and 90º elbow configurations are

available with female pipe threads. Three seal compounds are available - Hyspan

Barco proprietary Compound 11 composition seals, Compound 23 Teflon®, and

Compound 24 glass filled Teflon®.

Standard Series Ball Joints are ideally suited for machinery applications as an

alternative to hose assemblies and for seismic isolation.

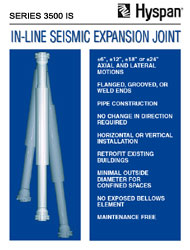

Series 3500 IS In-Line

Seismic Expansion Joint

Hyspan Barco ball joints are combined with Hyspan

Series 3500 Externally Pressurized Expansion Joints to provide standard

products 2" through 12" NPS designed for +/-6", +/-12", +/-18" or +/-24"

combined axial and lateral movement. They are designed as direct connections in

vertical or horizontal pipe runs, and do not require a change of direction.

Canadian Registration

Canadian Registration

Hyspan Barco Ball Joints have been approved for use throughout Canada under CRN

OD9278.59870YTNADD32.

Teflon® is a registered trademark of Dupont.

Grafoil® is a registered

trademark of UCAR.

|

|

Canadian Registration

Canadian Registration