|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

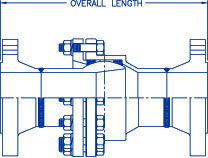

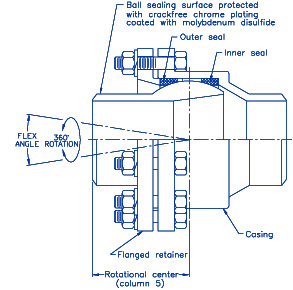

Dimensional DataType N Style I Ball Joints

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Nominal Size (NPS) |

Size Code |

Flex Angle (degrees) |

Outside Diameter (inches) |

Rotational Center (inches) |

| 2 1/2 | -40 | 23 | 5.94 | 3.50 |

| 3 | -48 | 22 | 7.19 | 4.25 |

| 4 | -64 | 25 | 9.75 | 5.50 |

| 5 | -65 | 25 | 11.28 | 6.00 |

| 6 | -66 | 23 | 12.38 | 7.19 |

| 8 | -68 | 17 | 14.75 | 8.00 |

| 10 | -70 | 16.5 | 17.13 | 8.25 |

| 12 | -72 | 15 | 19.75 | 8.69 |

| 14 | -74 | 15.25 | 22.50 | 10.06 |

| 16 | -76 | 15.5 | 25.25 | 11.25 |

| 18 | -78 | 15 | 26.75 | 12.50 |

| 20 | -80 | 15.5 | 30.00 | 11.50 |

| 24 | -84 | 15 | 35.25 | 16.00 |

| 30 | -90 | 15 | 42.62 | 18.00 |

| 1 | 3 | 3 | 4 | 5 |

| Weld End BB-31020 |

|

| Overall Length (inches) |

Weight (lbs) |

| 6.75 | 13 |

| 7.88 | 21 |

| 11.00 | 63 |

| 12.00 | 95 |

| 14.25 | 122 |

| 15.94 | 190 |

| 16.50 | 262 |

| 17.79 | 380 |

| 19.50 | 520 |

| 22.66 | 736 |

| 23.38 | 820 |

| 24.00 | 940 |

| 29.35 | 1375 |

| 34.77 | 2090 |

| 6 | 7 |

|

150 lb. Flanged BB-31533 |

|

| Overall Length (inches) |

Weight (lbs) |

| 12.5 | 29 |

| 13.63 | 41 |

| 17.25 | 93 |

| 19.25 | 133 |

| 21.5 | 170 |

| 24.19 | 268 |

| 24.75 | 366 |

| 27.04 | 540 |

| 29.75 | 740 |

| 32.91 | 1016 |

| 34.63 | 1140 |

| 35.63 | 1330 |

| 41.6 | 1925 |

| 45.78 | 2810.00 |

| 8 | 9 |

|

300 lb. Flanged BB-31536 |

|

| Overall Length (inches) |

Weight (lbs) |

| 13 | 37 |

| 14.38 | 51 |

| 18 | 113 |

| 20 | 159 |

| 22.25 | 206 |

| 24.94 | 324 |

| 26 | 444 |

| 28.29 | 660 |

| 31 | 880 |

| 34.41 | 1236 |

| 36.13 | 1460 |

| 37 | 1740 |

| 42.85 | 2535 |

| 51.52 | 3950 |

| 10 | 11 |

Flex Torque

|

|

|||||

Seal Descriptions and Pressure Temperature Ratings

|

|

Ordering Instructions

To order or specify Hyspan Barco Ball Joints state the complete part number which includes; the basic Assembly Number selected from the illustrations, the Size Code from Column 2 of the Dimensional Data tabulation and the Seal Code based on the seal composition required.

Installation and Maintenance Procedures

Proper application and maintenance of ball joints is important. Refer to Installation and Maintenance Procedures for Type N Style I ball joints for the correct procedures including disassembly and seal replacement.

Teflon® is a registered trademark of Dupont.

Grafoil® is a registered trademark of UCAR.

|

|

|

Copyright © Hyspan Precision Products, Inc. 2005. All rights reserved.

|

|

Hyspan Barco Type N Style I Ball Joints

Hyspan Barco Type N Style I Ball Joints