Hyspan Barco ASME Class Ball Joints

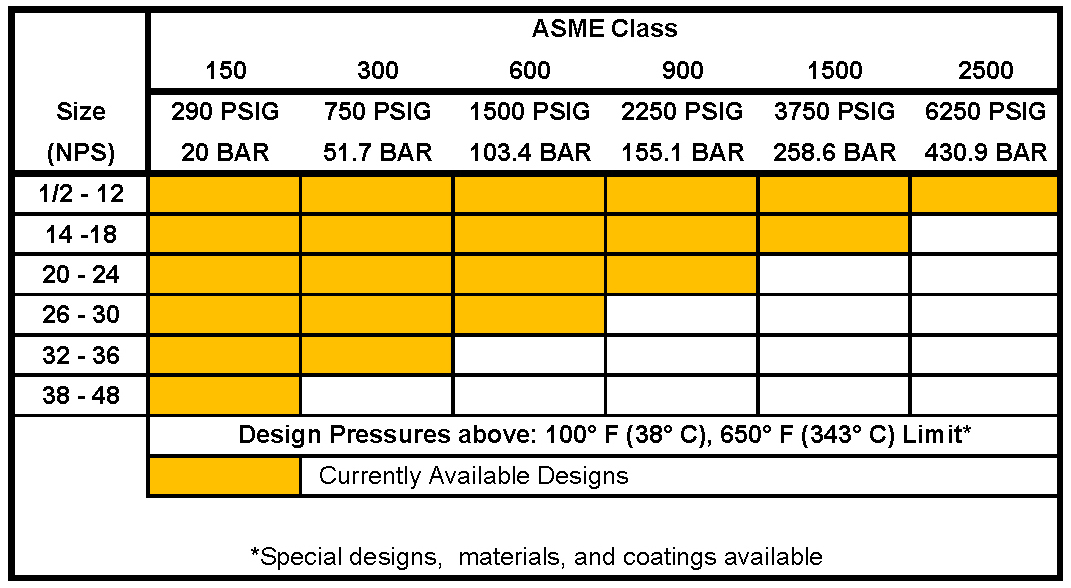

ASME Class Ball Joints are designed to conform to the ratings

established for ASME butt weld valves at 100║ F. Designs are available from 150

lb. through 2500 lb. They are recommended for use in ASME B31.1 and B31.3 piping

systems. Hyspan Barco ASME Class Ball Joints have been widely accepted for

chemical and petroleum system applications including oil field wellheads, oil

exploration drilling ships and platforms, and high pressure steam and hot water.

The sealing systems consist of optional seal materials including ductile

iron, chrome-moly alloy steel, and high nickel alloys 600 and 625 combined with

injected graphite flakes with synthetic oil-Grafoil«

Flexible Graphite packing. Grafoil« packing can be injected after installation

if necessary, and the ball joints can be disassembled for maintenance.

All Hyspan Barco ASME Class Ball Joints are designed for a total flex angle of

15░.

ASME Class Ball Joints have been fire tested in accordance with API 6FA and

approved by ABS Americas and Lloyd's Register for shipboard applications.

|

|

|

|

6" NPS, Series 6600 ASME Type Class, 2500 Ball Joint

|

|

|

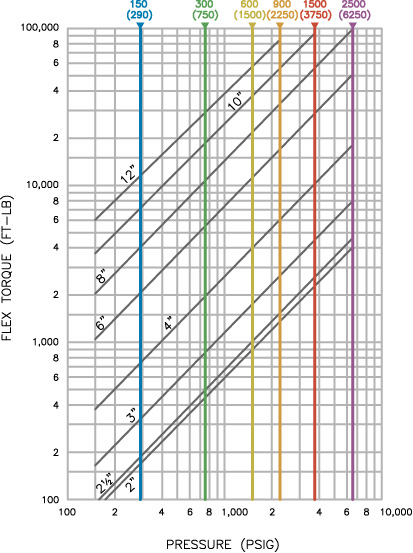

Flex Torque/Pressure

ASME Class Hyspan Barco Ball Joints

Installation and Maintenance Procedures

Proper application and maintenance of ball joints is important. Refer to the Installation and Maintenance Procedures for ASME Class ball joints for the correct procedures including disassembly and seal replacement.

Grafoil® is a registered trademark of Graftech (formerly UCAR)

|