|

|

|

|

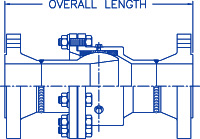

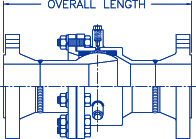

Hyspan Barco Type N Style II, Style III & III-V Ball Joints

|

|

|

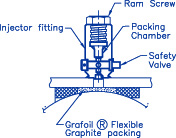

Type N Style II, III & III-V ball joints combine the inner and outer seals that are common to all Hyspan Barco ball joints with injected graphite flakes with synthetic oil carrier, Grafoil® Flexible Graphite packing. This combination allows the use of a wide variety of high strength seal materials with the lubrication and high temperature sealing capability of Grafoil®.

The ball sealing surface of Type N Style II, III, & III-V ball joints is protected with two mils of chrome plating consisting of one mil of hard chrome over one mil of crack free chrome, and baked-on molybdenum disulfide lubricant coating.

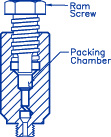

Type N Style II ball joints can be repacked after installation in the system if necessary. Type N Style III and III-V ball joints can be repacked under pressure. All configurations can be completely disassembled for maintenance.

|

|

|

Type N Style II, III & III-V ball joints are used in steam and hot water distribution systems, chemical and petroleum plants, oil exploration drilling ships and platforms, and many other critical installations. All standard configurations are warranted for five years.

Higher pressure designs and designs conforming to the ASME code are available as Hyspan Barco ASME Class Ball Joints.

Type N Style III ball joints have been fire tested in accordance with API 6FA and approved by ABS Americas and Lloyd's Register for shipboard applications.

|

|

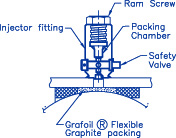

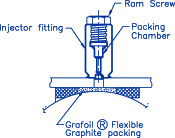

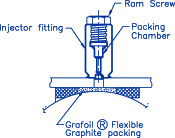

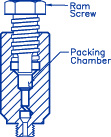

Style III-V Injector

|

|

|

Style III Injector

|

|

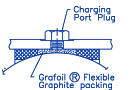

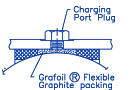

Style II Plugged Port

|

|

|

|

|

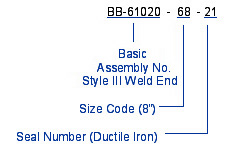

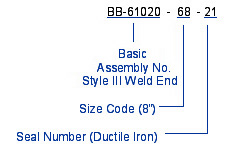

Part Number

BB-41020 (Style II )

|

|

Part Numbers

BB-61020 (Style III)

BB-66020 (Style III-V)

|

|

|

|

Part Numbers

BB-41533 (150 lb. Style II )

BB-41536 (300 lb. Style II )

|

|

Part Numbers

BB-61533 (150 lb. Style III)

BB-66533 (150 lb. Style III-V)

BB-61536 (300 lb. Style III)

BB-66536 (300 lb. Style III-V)

|

|

|

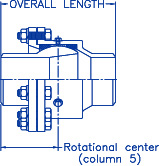

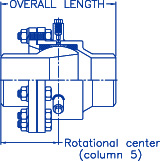

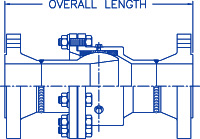

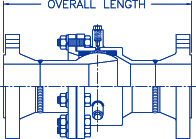

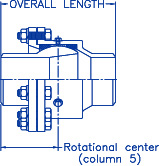

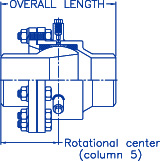

Dimensional Data

Type N Style II, Style III and III-V Ball Joints

Nominal

Size

(NPS)

|

Size

Code

|

Flex

Angle

(degrees)

|

Outside

Diameter

(inches)

|

Rotational

Center

(inches)

|

| 2 1/2 |

-40 |

23 |

5.94 |

3.50 |

| 3 |

-48 |

22 |

7.19 |

4.25 |

| 4 |

-64 |

25 |

9.75 |

5.50 |

| 5 |

-65 |

25 |

11.28 |

6.00 |

| 6 |

-66 |

23 |

12.38 |

7.19 |

| 8 |

-68 |

17 |

14.75 |

8.00 |

| 10 |

-70 |

16.5 |

17.13 |

8.25 |

| 12 |

-72 |

15 |

19.75 |

8.69 |

| 14 |

-74 |

15.25 |

22.50 |

10.06 |

| 16 |

-76 |

15.5 |

25.25 |

11.25 |

| 18 |

-78 |

15 |

26.75 |

12.50 |

| 20 |

-80 |

15.5 |

30.00 |

11.50 |

| 24 |

-84 |

15 |

35.25 |

16.00 |

| 30 |

-90 |

15 |

42.62 |

18.00 |

| 1 |

3 |

3 |

4 |

5 |

|

Weld End

BB-41020

BB-61020

BB-66020

|

Overall

Length

(inches)

|

Weight

(lbs)

|

| 6.75 |

13 |

| 7.88 |

21 |

| 11.00 |

63 |

| 12.00 |

95 |

| 14.25 |

122 |

| 15.94 |

190 |

| 16.50 |

262 |

| 17.79 |

380 |

| 19.50 |

520 |

| 22.66 |

736 |

| 23.38 |

820 |

| 24.00 |

940 |

| 29.35 |

1375 |

| 34.77 |

2090 |

| 6 |

7 |

|

150 lb. Flanged

BB-41533

BB-61533

BB-66533

|

Overall

Length

(inches)

|

Weight

(lbs)

|

| 12.5 |

29 |

| 13.63 |

41 |

| 17.25 |

93 |

| 19.25 |

133 |

| 21.5 |

170 |

| 24.19 |

268 |

| 24.75 |

366 |

| 27.04 |

540 |

| 29.75 |

740 |

| 32.91 |

1016 |

| 34.63 |

1140 |

| 35.63 |

1330 |

| 41.6 |

1925 |

| 45.78 |

2810.00 |

| 8 |

9 |

|

300 lb. Flanged

BB-41536

BB-61536

BB-66536

|

Overall

Length

(inches)

|

Weight

(lbs)

|

| 13 |

37 |

| 14.38 |

51 |

| 18 |

113 |

| 20 |

159 |

| 22.25 |

206 |

| 24.94 |

324 |

| 26 |

444 |

| 28.29 |

660 |

| 31 |

880 |

| 34.41 |

1236 |

| 36.13 |

1460 |

| 37 |

1740 |

| 42.85 |

2535 |

| 51.52 |

3950 |

| 10 |

11 |

|

Flex Torque

Flex torque is the moment (ft.-lbs.) at break-a-way to angularly displace a ball joint. Because the pressure thrust is reacted by the seals the flex torque is a function of pressure as illustrated by the adjacent graphs for Number

19, 21 and

39 seals.

The values given are for steam service. For water or oil service the torque values are 45% less.

Flex Torque

Flex Torque

Type N Style II, III & III-V Ball Joints

Number 19, 21 & 39 Seals

|

|

Flex Torque Type N Style II, III & III-V Ball Joints Number 19, 21 & 39 Seals

Flex Torque Type N Style II, III & III-V Ball Joints Number 19, 21 & 39 Seals

|

|

Flex Torque Type N Style II, III & III-V Ball Joints Number 19, 21 & 39 Seals

Flex Torque Type N Style II, III & III-V Ball Joints Number 19, 21 & 39 Seals

|

|

|

Seal Descriptions and Pressure Temperature Ratings

Seal Number 19

Compound 19 is a pressure molded proprietary seal compound recommended for general purpose applications for steam, hot water and oil systems. Compound 19 has the highest pressure/temperature ratings of the available non-metallic seal materials.

Rated for service at temperatures from -50° F to 525° F.

Seal Number 21

Compound 21 seals are cast ductile iron and precision machined. The ductile iron combined with the chrome plated sealing surface of the ball provide a low friction long life seal.

Rated for service at temperatures from -20° F to 650° F with standard materials of construction.

Seal Number 39

Compound 39 seals are machined from Alloy 625 high nickel stainless steel. Alloy 625 has very high strength combined with exceptionally high corrosion resistance.

Number 39 seals are normally used in Type N packed ball joints made from special materials such as stainless steel and high chrome steel alloys. The temperature/pressure ratings are dependent on all of the materials used for construction .

Seal Number 45

Compound 45 seals are machined from ASME A-182 F11 chrome-moly steel forgings. Alloy F11 is a very high strength steel which can be used for higher temperature applications.

Number 45 seals are normally used in Type N packed ball joints made from special materials flange including high chrome steel alloys. The temperature/pressure ratings are dependent on all of the materials used for construction.

|

|

Pressure/Temperature Ratings Number 19 Composition Seal Type N Style II, III & III-V Weld End & 300 lb. Flanged Pressure/Temperature Ratings Number 19 Composition Seal Type N Style II, III & III-V Weld End & 300 lb. Flanged

|

|

Pressure/Temperature Ratings Number 19 Composition Seal Type N Style II, III & III-V

Pressure/Temperature Ratings Number 19 Composition Seal Type N Style II, III & III-V

150 lb. Flanged

|

|

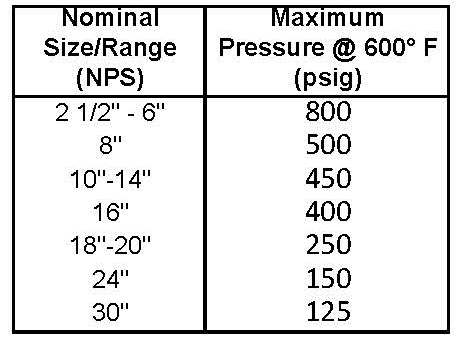

Pressure/Temperature Ratings

Number 21 Ductile Iron Seal

Type N Style II, III & III-V Weld End

The rated pressure for flanged is determined by the rating. Consult the applicable code for the allowable pressure at the design temperature.

|

|

Accessories

Recharge Cylinder

Part Number 10-64416-43

Type N Style II ball joints are designed to be sealed after installation if a leak develops. A recharge cylinder that is designed to be temporarily installed in the charging ports is available.

Reload Kits

Part Number 10-64715-00

Flexible graphite packing material is available as pellets designed to be inserted into Type N Style II, III and III-V recharge cylinders. Each kit contains 13 pellets.

Insulation Covers

Removable, reusable insulation covers as specially made to fit all styles and configurations of Hyspan Barco ball joints. A full range of insulation and jacketing materials are available for all design temperatures. Covers for the Style III and III-V ball joints have pre-cut openings to allow access to recharge cylinders.

|

|

|

Style II Recharge Cylinder

|

|

Recharge Kit Pellets

|

|

|

|

Ordering Instructions

To order or specify Hyspan Barco Ball joints state the complete part number which includes; the basic Assembly Number selected from the illustrations, the Size Code from Column 2 of the Dimensional Data tabulation, and the Seal Code based on the seal material required.

|

|

|

Installation and Maintenance Procedures

Proper application and maintenance of ball joints is important. Refer to Installation and Maintenance Procedures for Type N Style II, Type N Style III and Type N Style III-V for the correct procedures including disassembly and seal replacement.

Five (5) Year Limited Warranty

This warranty is given by HYSPAN PRECISION PRODUCTS, INC. (HYSPAN) for the benefit of the first purchasers for use of Hyspan Barco Type N Style II, Style III and Style III-V Ball Joints manufactured by HYSPAN to standard catalog construction. The product is warranted to be free from defects in material and workmanship, and to be leak-free for a period of five (5) years from the date of shipment by HYSPAN in accordance with the following conditions:

- The design pressure and temperature are not exceeded -including surge and upset conditions.

- The installation conforms to HYSPAN installation procedures and approved practice for anchoring, supporting and guiding, and generally accepted good piping practice.

- Substances in contact with all internal and external surfaces must be compatible with the materials of construction, including all contaminates.

- The warranty shall be limited to the replacement by HYSPAN of the same model Hyspan Barco Ball joint, and payment for transportation of the replacement assembly by the least expensive method. Labor, material and other costs related to the failure or replacement of the expansion joint are not included. HYSPAN shall not be liable for damage or delay suffered by the purchaser regardless of whether such damages are general, special or consequential in nature, whether caused by defective material or workmanship, or whether caused by HYSPAN'S negligence regardless of the degree.

- HYSPAN warranties satisfactory leak-free performance. If leakage occurs through the packing and cannot be prevented by the addition of packing by the user in accordance with the field packing installation instructions, HYSPAN will repair or replace the ball joint within the terms of this warranty.

- This warranty is expressed in lieu of all other warranties, expressed or implied, including the warranty of merchantability, the implied warranty of fitness for a particular purpose, and all other obligations or liabilities on the part of HYSPAN, and it neither assumes nor authorizes any other persons to assume for HYSPAN any other liabilities in connection with the sale of the products.

- The warranty is limited to installations in the United States, Puerto Rico and Canada.

The purchaser shall advise the HYSPAN factory of any warranty claim including the nature of the failure. HYSPAN shall provide return goods authorization and shipping directions to return the failed joint to the factory. A mutually agreeable delivery schedule and method of shipping the replacement shall be established. The purchaser shall furnish a confirming purchase order and is obligated to the current replacement cost of the joint and shipping expense. Upon receipt of the failed product, the cause of failure shall be determined by the factory at no expense to the purchaser. A credit shall be issued by the factory for the replacement cost and least expensive shipping for valid warranty claims. In the event of a dispute, HYSPAN shall furnish the failed product to the purchaser or their representative for failure analysis.

Grafoil® is a registered trademark of UCAR.

Teflon® is a registered trademark of Dupont.

|

|