|

|

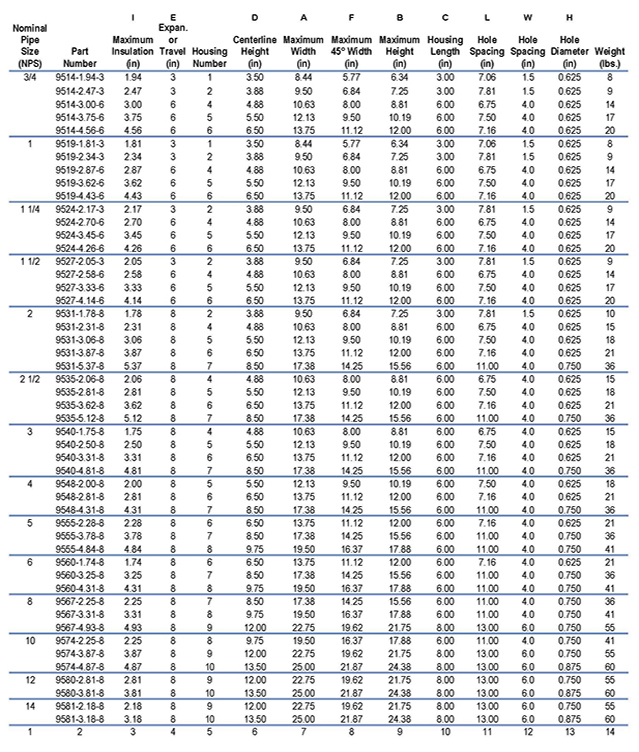

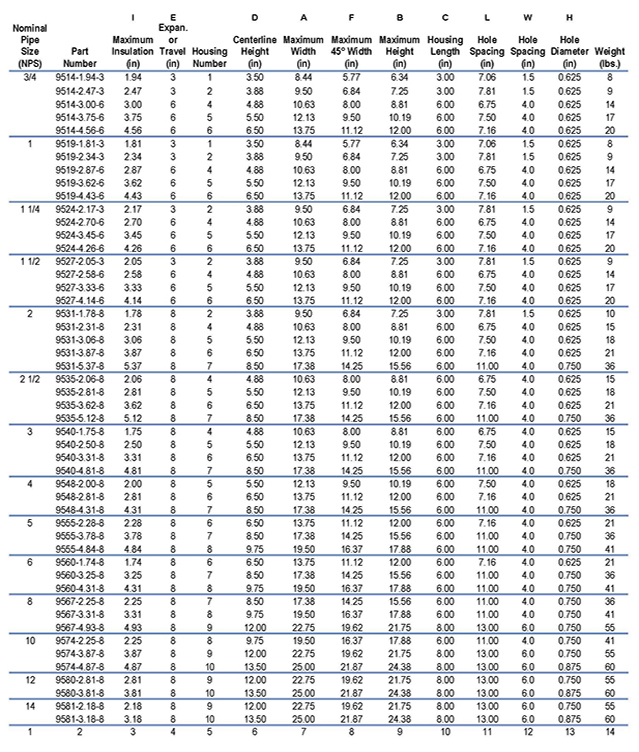

Series 9500 Copper Tube

Alignment Guide

|

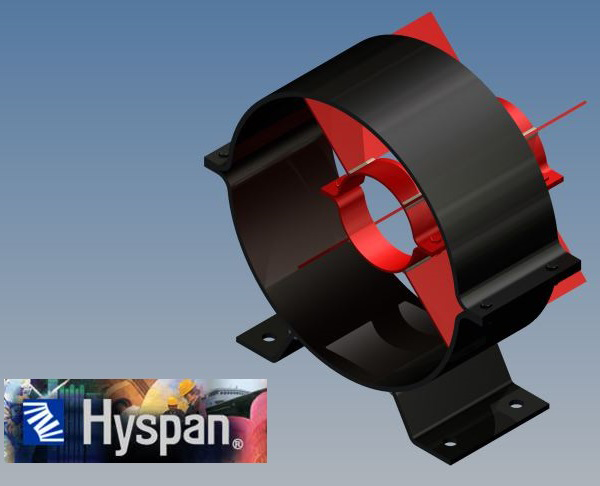

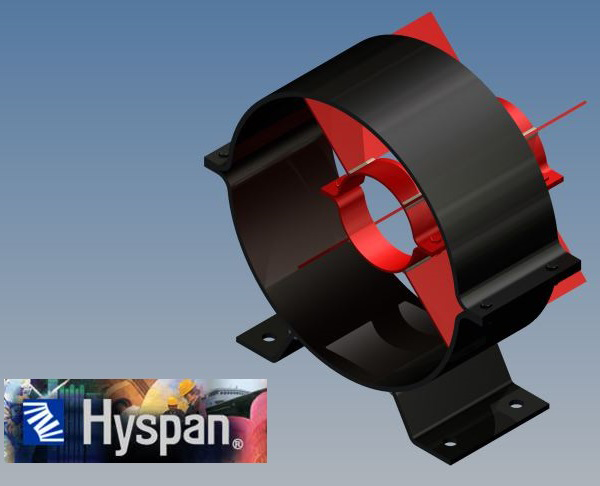

Series 9500

Alignment Guides

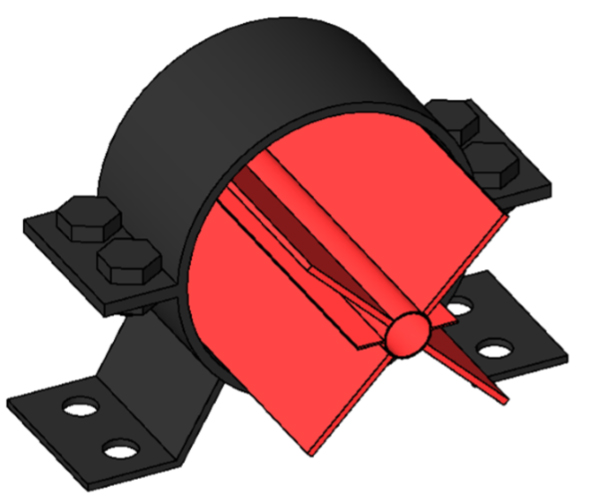

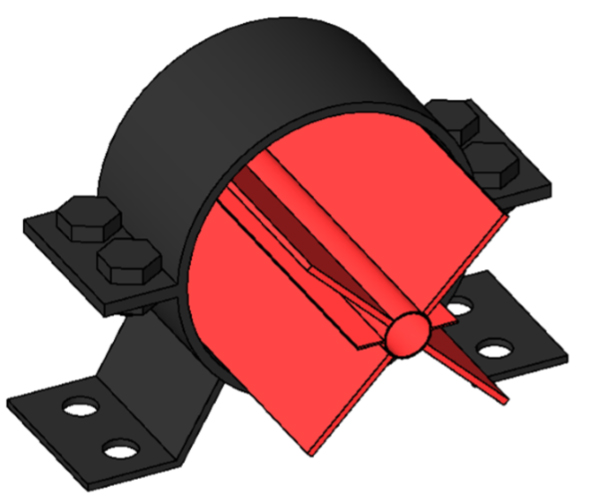

Hyspan Series 9500 Alignment Guides are designed to be installed adjacent to

expansion joints and as intermediate guides in steel pipe and copper tube runs

to maintain the centerline of the pipe/tube. They are also used in pipe loop

systems to provide stability and motion direction control. These

state-of-the-art alignment guides are advanced, large-structure, low-mass

technology resulting in minimum weight while providing 3-Dimensional alignment

using the conservative Spider & Cylinder arrangement.

Pipe or copper tube systems that incorporate expansion joints, ball joints, or

loops to absorb expansion must include three additional major elements: main

and/or intermediate anchors, supports, and alignment guides. Main anchors are

required in systems that include unrestrained expansion joints to react pressure

thrust, the expansion joint spring or friction force, and the friction force of

the guides and supports. Intermediate anchors are required in systems where

pressure thrust is restrained, but the expansion joint or loop spring or

friction force, guide, and support friction forces must be reacted. Supports

must be designed to react the weight of the pipe/tube and media. Alignment

guides are required to maintain the pipe/tube centerline axis to expansion

joints and throughout the intermediate portion of the run to also prevent bowing

and resist buckling.

The alignment guides requirements for Hyspan products are given in the

Applications section of each product catalog. These requirements follow the

Standards of the Expansion Joint Manufactures Association, Inc. Expansion joints

that do not include internal guides require an alignment guide to be located 4

diameters from the face of the expansion joint, and an additional guide 14

diameters from the first guide. Expansion joints with internal guides require

only one alignment guide to be located 10-14 diameters from the expansion joint.

The maximum alignment guide spacing in the intermediate portion of the run is a function of the

pipe/tube properties (modulus of elasticity and moment of inertia), the design

pressure, and the expansion joint effective area and spring force. Refer to the

Applications section of Hyspan expansion joint catalogs for the individual

product guiding requirements.

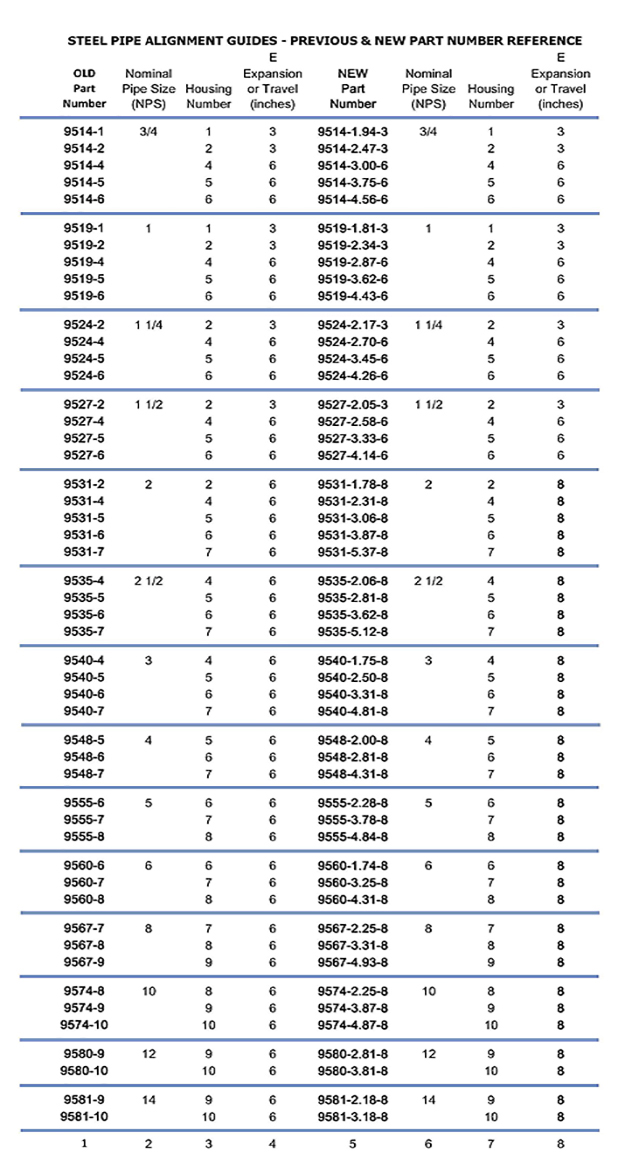

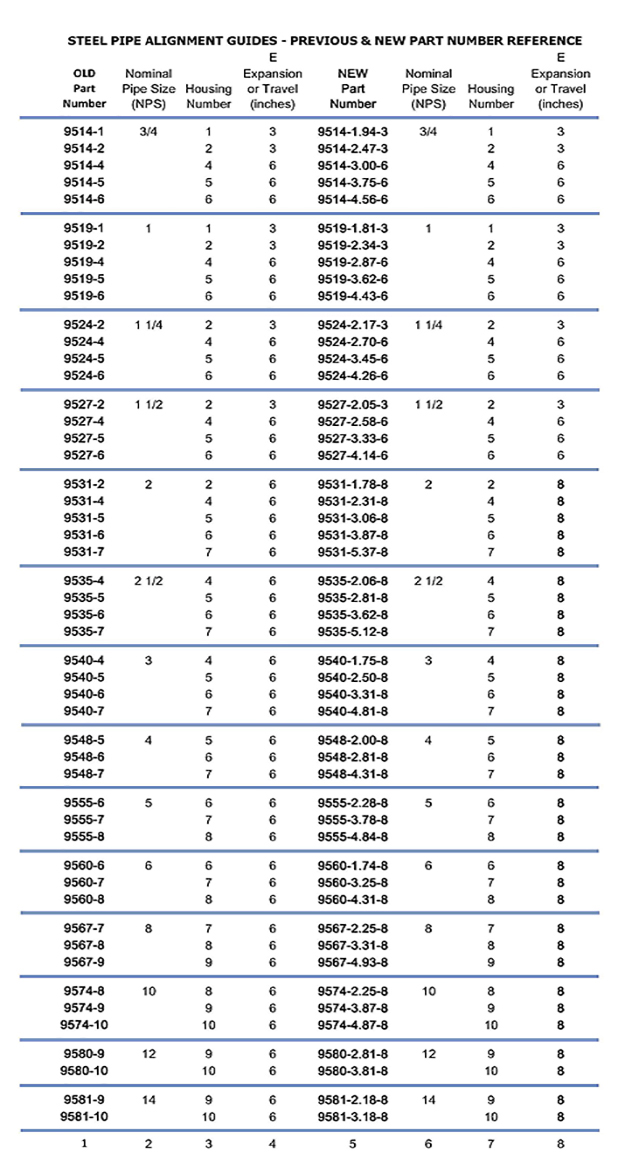

Steel Pipe Alignment Guides

Hyspan manufactures and inventories standard alignment guides for nominal pipe

size (NPS) steel pipe from 3/4” through 14” with varying insulation

thickness. Construction is heavy gauge pressed steel with precision drilled

bolting. All surfaces are coated with protective black enamel paint. Hot dipped

galvanizing or all stainless steel construction are also available. In tight

spaces, rotated housings are available. The maximum operating temperature is 500°F.

All stainless steel construction is also available to provide greater corrosion

resistance, higher temperatures, or cryogenic systems.

|

BUILDING INFORMATION MODELING (BIM)

REVIT and .stp support/images

are available. |

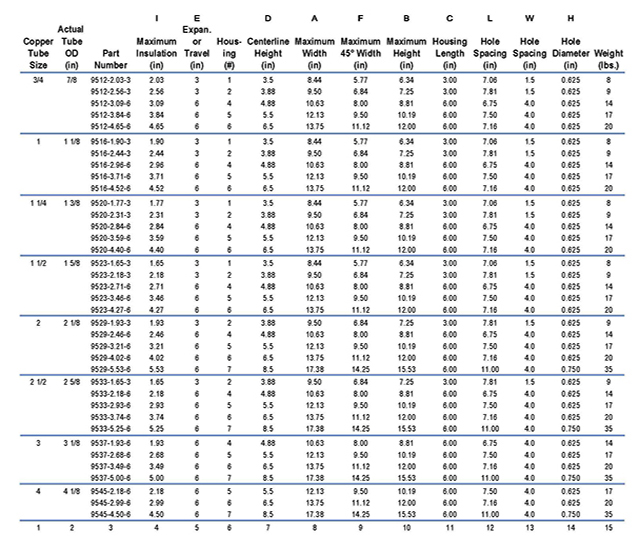

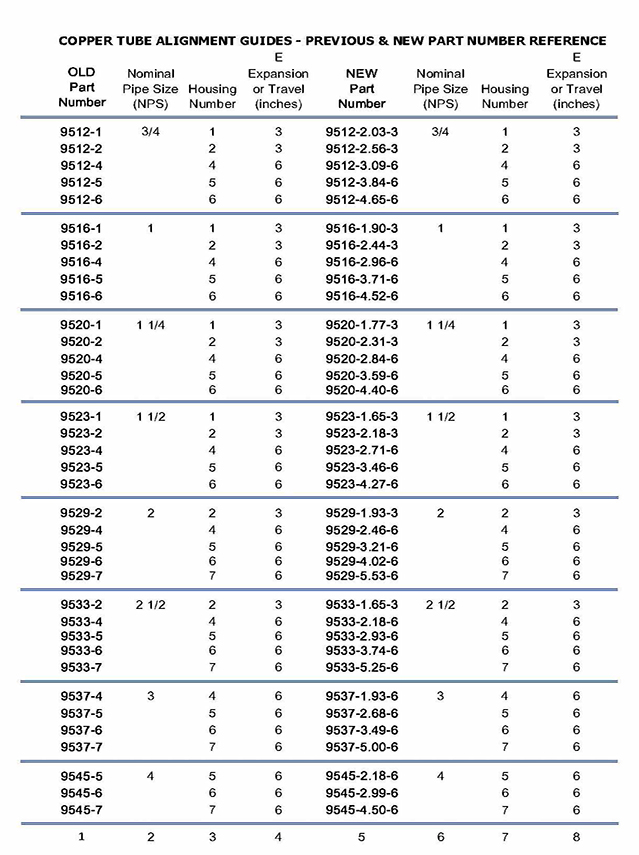

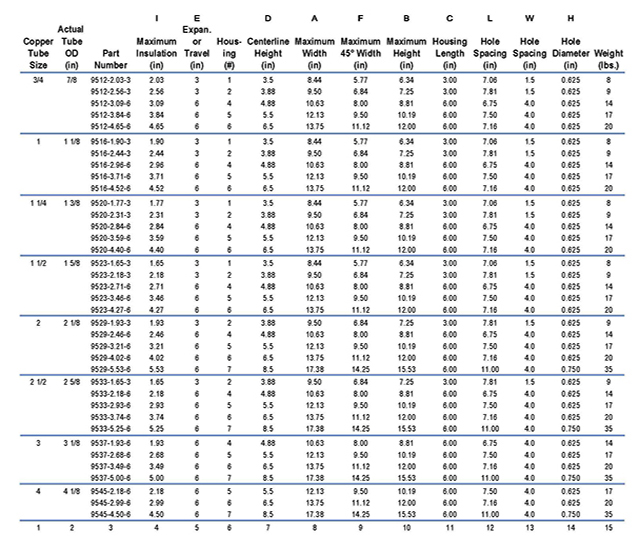

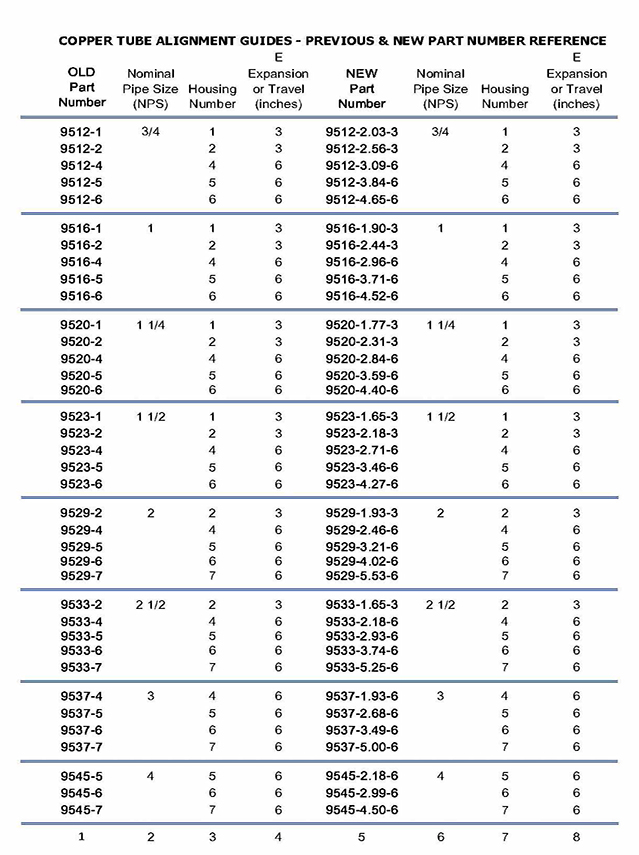

Copper Tube Alignment Guides

Hyspan manufactures and inventories standard alignment guides for standard size copper tube from

3/4” through 4” with varying insulation thickness. Construction is

heavy gauge pressed steel with precision drilled bolting. All surfaces are

coated with protective black enamel paint. The interface with the copper tube is

coated with a permanent heavy dielectric material. Hot dipped galvanizing is

available as an option. In tight spaces, rotated housings are available. The

maximum operating temperature is 400°F. All stainless steel construction is

also available to provide greater corrosion resistance.

|

9500 Pipe and Copper Tube Alignment Guide Options:

Hot

dipped galvanized structural components, -GV Hot

dipped galvanized structural components, -GV

All

304 stainless steel construction, -SS All

304 stainless steel construction, -SS

45-degree

housing and spider, -45 45-degree

housing and spider, -45 |

-

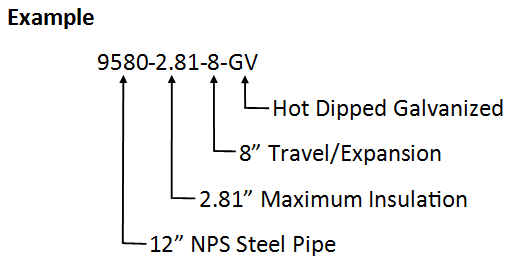

Product Selection (Part Number) & Ordering Instructions:

1) Select Steel Pipe or Copper Tube, then locate correct Table

-

2) Select the size

-

3) Select insulation clearance: a maximum value equal to or greater than the insulation thickness to be

installed

-

4) Verify the Alignment Guide Expansion/Travel stated is equal or greater than the motion occurring at the guide

location. For additional expansion increase the last part number indicator as

needed

-

5) For Hot dipped galvanized steel or stainless steel materials, select one of

these options below in the example.

-

6) Confirm the guide housing “A” spacing will fit into the system. If it does

not, select the “-45” degree housing and spider option and re-verify the

spacing.

-

|