|

Venturi flow measuring instruments are included in the category of Bernoulli flow obstruction theory devices that also includes the thin plate orifice and flow nozzles. For a complete glossary and technical information regarding these flow measurement methods, refer to ASME MFC-3M Measurement of Fluid Flow in Pipes Using Orifice, Nozzle and Venturi and ASME MFC-1M Glossary of Terms Used in the Measurement of Fluid Flow in Pipes

ACCURACY: The degree of conformity of the indicated (measured) value to the true value. The accuracy of a venturi based on empirical data varies with the diameter and method of construction. By individual calibration the accuracy can be +/- ½%.

BETA RATIO (β): The ratio of the inside of the diameter throat of the venturi to the inside diameter of the pipe at the plane of the upstream Pressure Taps.

CAPACITY CURVES: Graphs used for the selection of a venturi for flow measurement – graphs Differential Pressure v. Flow Rate for individual pipe sizes and Beta Ratios.

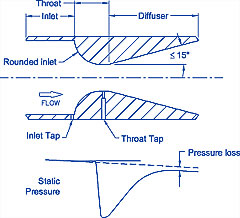

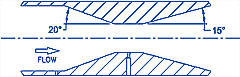

CLASSICAL VENTURI: The first scientist to test conical contractions and expansions was Giovanni Venturi. American engineer, Clemens Herschel, invented the classical venturi which consists of a 21° conical contraction, straight throat and 7-15° conical expansion. The Discharge Coefficient is nearly unity and the non-recoverable Head Loss is very small for this configuration. See Venturi.

DIFFERENTIAL PRESSURE (ΔP): The Static Pressure difference between the upstream inside pipe diameter and the throat diameter resulting from the reduced area of the cross section.

DISCHARGE COEFFICIENT: A dimensionless coefficient equal to the ratio of the actual rate of flow divided by the theoretical rate of flow. It is a measure of the deviation of a venturi configuration from the ideal.

END CODE: Method used by Hyspan Barco to identify the end connection of a venturi, -31 is threaded, -41 is flanged (150 lb.), -61 is beveled for welding, -81 is grooved.

FACTORY MUTUAL: When used in this web site, refers to the fire protection product approval services of the Factory Mutual Insurance Company (FM Global). Hyspan venturis are FM Approved for fire pump flow testing.

FLOW RATE: The quantity of fluid flowing through a cross section of pipe per unit of time. For commercial applications commonly measured in gallons per minute.

GPM: Refers to commonly used units used to describe flow rate – gallons per minute.

HEAD LOSS: See Non-Recoverable Pressure Loss.

INCHES OF WATER: Refers to commonly used units of pressure change used to describe Differential Pressure and Head Loss.

NFPA: Refers to the National Fire Protection Association, the publisher of standards related to the testing of fire protection systems.

NON-RECOVERABLE PRESSURE LOSS: The loss of pressure at a specific flow rate as a result of a flow measuring instrument. The venturi has the lowest loss of the three Bernoulli theory devices.

PRESSURE TAPS: When used in the context of this web site, refers to the locations of the static pressure measurements at the upstream pipe and the throat of the venturi. Sometimes referred to as wall taps.

REYNOLDS NUMBER: A dimensionless parameter expressing the ratio between inertia and viscous forces at a specific cross section.

SIZE CODE: Method used by Hyspan Barco to identify the size (diameter) of a venturi i.e. 08 refers to a ½" nominal pipe size venturi.

STATIC PRESSURE: The pressure that is independent of the kinetic energy of the fluid. Measurements are made along the surface of a pipe or the throat of a venturi. See Pressure Taps.

THROAT: The cylindrical section of the venturi which represents the smallest cross section of the venturi. See Venturi.

VENTURI: A flow measuring device consisting of a cylindrical entrance section, converging section, cylindrical throat section and a diverging section. Refer to Classical Venturi. Hyspan Barco venturi designs incorporate a smooth rounded converging section conforming to ISA 1932 shape (International Organization for Standardization) transitioning to a 7.5° conical diverging section.

|

|